Scientists from St. Petersburg Polytechnic University named after Peter the Great (SPbPU) have developed a robotic dispensing system that can optimize work in microelectronics, mechanical engineering and the chemical industry. According to the university's press service, the device surpasses existing analogues on the market in terms of functionality.

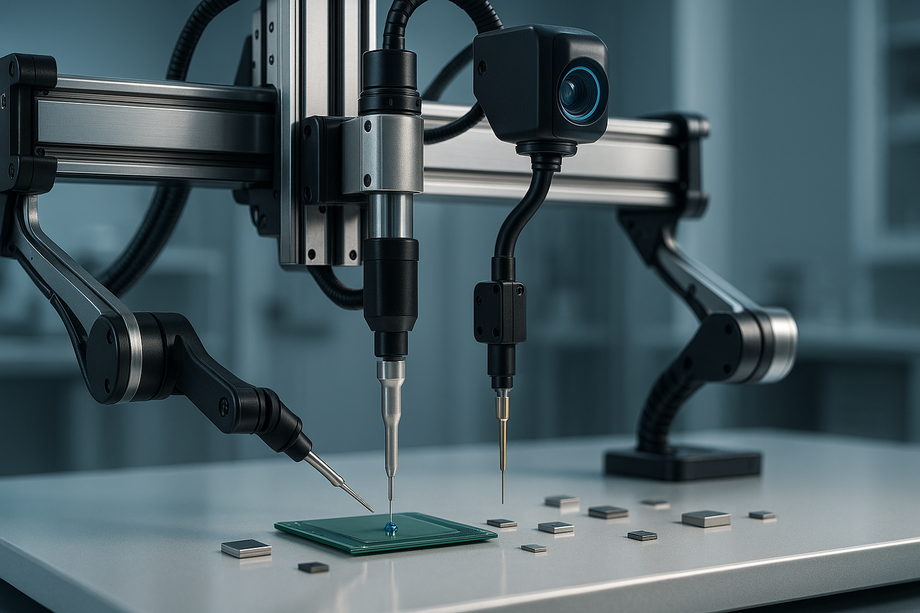

The robot is a three-coordinate device with a dispensing module and a machine vision system for feedback. It is capable of working with polymers, sealants, solder pastes, liquid suspensions and fusible glasses. Dosing is carried out by a piston method or using air pressure, which allows you to work with materials of various viscosities.

A key feature is the integration of machine vision, which allows the robot's actions to be corrected in real time along an unprogrammed trajectory. This simplifies the application of sealants, the laying of products made of silicone and polyurethane of complex shapes, as well as the precise alignment of micro-optical elements. The operator can control the robot through color differentiation of objects, without having to write complex programs.

The technical parameters of the robot allow it to be used in the production of microelectronics: positioning accuracy up to 20 microns, movement speed up to 300 mm/s, working space 300x300 mm with the possibility of expansion. The system supports the installation of two manipulators and six peripheral devices.

The development was carried out by a team from the Nanotechnology and Coatings Scientific Center, including designers, electronics engineers, IT specialists and industrial designers. During the work, more than eight versions of the design were assembled, and one of the models successfully worked more than 100,000 cycles without loss of accuracy. The robot is ready for mass production and can be integrated into industrial lines.