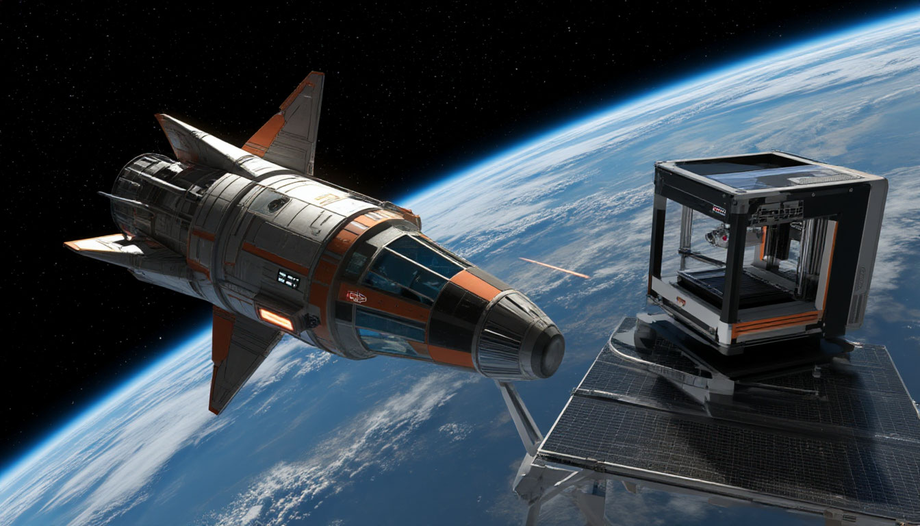

On the initiative of the Rocket and Space Corporation "Energia" named after S. P. Korolev, samples of PLA plastic obtained using a 3D printer on the International Space Station (ISS) were delivered to Earth and transferred to KuzSTU for further testing. These are the first samples made in zero gravity. The results of the experiment may change the approach to the production of parts in space.

Scientists conducted a series of tests to compare the characteristics of plastics made in space with those obtained on Earth. The results showed that "extraterrestrial" samples are not inferior in strength and mechanical characteristics to terrestrial counterparts. This confirms the possibility of creating parts in space using 3D printing.

Associate Professor of KuzSTU Nikolai Ababkov noted that the successful printing of parts in space opens up new prospects for creating the necessary components in orbit. Scientists paid special attention to the mechanical properties of the material, such as tension, bending and impact loads, as well as strength and hardness. The thermophysical characteristics and degree of crystallinity of the plastic were also investigated.

The importance of such research was also emphasized by the Vice-Rector of KuzSTU Kostikov.

Cosmonauts on the ISS, often unpredictably, may need various products for unscheduled replacement of failed parts or some new parts. Often these parts are critical products, and it is necessary to predict their behavior and service life in space conditions.

The manufacture of parts in space is crucial for the durability of spacecraft and the successful completion of long-term missions. Thus, the new development can greatly simplify the process of creating the necessary parts in zero gravity.

Read more materials on the topic:

Mars or the Moon?: a historian of astronautics told when Russia will be able to conquer Mars

"Gradient" magnetic material developed by Kazan physicists

Russian scientists have for the first time recorded "runaway" electrons in a laboratory sprite