The European Space Agency - ESA - has announced a unique experiment to facilitate future research on the Moon and Mars. As part of the Cygnus NG-20 supply mission, which launched on January 30, a 3D printer for metal printing was sent to the ISS.

It is assumed that the 3D printer will not only be able to create new tools in orbit, but also recycle fragments of old satellites for this purpose - this will form a closed space economy. Reusing materials will save time and resources associated with sending tools and cargo on a rocket, and will allow space researchers to print the necessary parts in orbit.

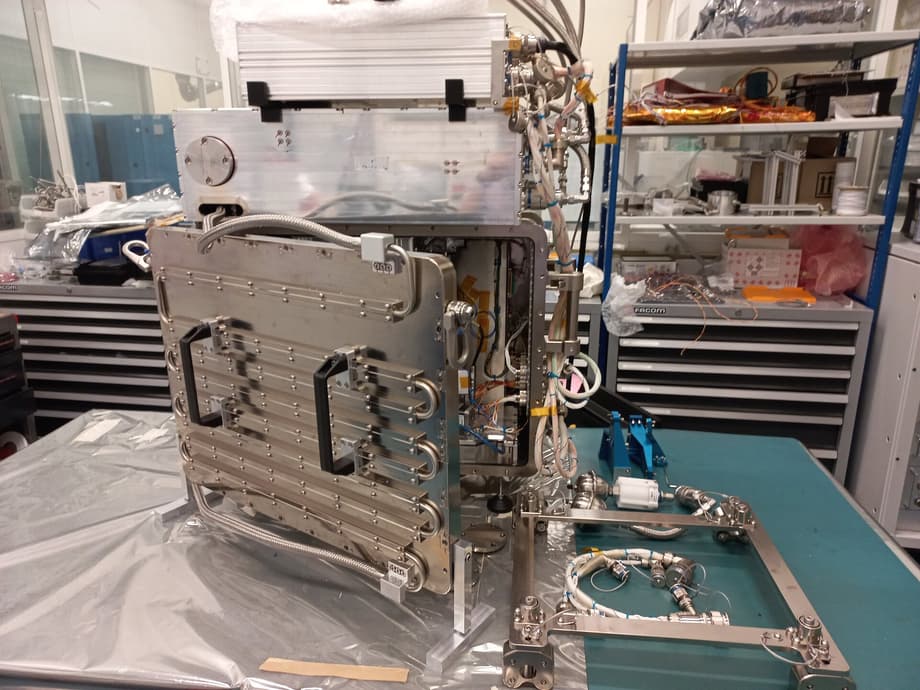

But that will be later. For now, ESA astronaut Andreas Mogensen must prepare and install a 3D printer weighing about 180 kg in the European Mark II pull-out rack in the ESA Columbus module. Printing will be carried out remotely, from Earth.

The complexity of 3D metal printing is that it uses high temperatures - the melting point of stainless steel is about 1400 °C, and the metal is melted using a laser. This creates risks for the crew and the station itself, but if everything works out, it will be a global breakthrough in space exploration.

The metal 3D printer uses stainless steel. A wire made of it is fed into the printing area and heated by a powerful laser, which is a million times more powerful than a regular laser pointer. When the wire is immersed in the melt pool, the end of the wire melts and the metal is added to the print.

The melt pool is very small, about a millimeter across, and the surface tension of the liquid metal holds it in place in zero gravity. The printer operates in a sealed enclosure to prevent excess heat or smoke from entering the space station's cabin. Before printing, the printer's internal oxygen atmosphere will be replaced with nitrogen, as hot stainless steel will oxidize when exposed to oxygen.

Four forms were chosen to test the performance of the Metal 3D printer. They will be compared to prints that were created on Earth. Each of the four prints is smaller than a soda can and weighs less than 250 grams.

After printing, astronaut Andreas will remove each form from the printer and pack it for safe shipment to Earth. One form will be sent to the European Astronaut Centre in Cologne, one to the Technical University of Denmark, and two to the European Space Research and Technology Centre. Specialists will conduct macro and microanalysis of the printed parts, study their thermal properties, analyze and identify differences in print quality and performance between space and Earth environments.

It is worth noting that Russia also plans to print new objects on board the ISS this year. The experiment using 4D bioprinting assumes the creation of tubular organs in zero gravity - the ureter, urethra and others - and sending them to Earth for study.